Cement production accounts for 8% of carbon dioxide emissions around the world, so Carbon Re has developed a cost-effective AI that identifies ways to lower emissions.

“Cement is one of the biggest contributors to climate change and carbon emissions,” Sherif Elsayed-Ali, co-founder and chief executive of Carbon Re tells GUV. “We produce globally around four billion tonnes of cement each year, which shows the scale of cement production on climate security.”

Indeed, the average global temperature has increased by at least 1.1 degrees Celsius since 1880, according to NASA’s Goddard Institute for Space Studies, with a majority of the increase having occurred since 1975. While many sectors have an impact, the industrial and manufacturing sector accounts for 24% in the US and cement production alone is responsible for 8% of all carbon dioxide emissions worldwide.

It is vital decarbonisation efforts progress quickly if we are to prevent catastrophic ecosystem collapses.

Carbon Re, a UK-based spinout of University of Cambridge and University College London, has developed artificial intelligence (AI) software called Delta Zero for energy-intensive industries. Delta Zero exploits data that’s already collected to support control room operators in optimising energy use and production whilst also saving costs.

The spinout was launched during the pandemic in 2020. Elsayed-Ali says: “We have quite an ambitious mission, to reduce gigatons of emissions every year eventually. We believe this can be done by tackling the hardest sector, the cement and steel industries, focusing at the moment on cement production.”

While the company is young, Elsayed-Ali brings considerable expertise from earlier career stops. Before joining Carbon Re, he spent nearly two years as a director of partnerships and director for AI climate at Element AI, a Canada-based artificial intelligence company where he was required to find solutions to climate change through application monitoring and machine learning techniques.

He also was a major figurehead for Amnesty International, spending more than 14 years with the organisation in various positions such as director of global issues and research. He also co-founded Amnesty Tech, the charity’s global technology human rights programme. Earlier in his career, he worked for the United Nations High Commissioner for Refugees.

“Carbon Re is leveraging the potential of machine learning and artificial intelligence to optimise the production of these materials today,” explains Elsayed-Ali. “Through providing an immediate response, we hope in the long term to support producers in creating upcoming solutions and new production processes that will bring us closer to zero carbon emissions materials.”

Understanding the technology behind Carbon Re

Carbon Re has been developing three variations of its AI software: Delta Zero Cement, Delta Zero Steel and Delta Zero Glass. None require any novel dedicated hardware, so Carbon Re can focus on the development of its machine learning technology.

Elsayed-Ali explains: “Cement is something we require to build our infrastructure, it is an important product to develop our large buildings like schools, hospitals and pavements. Cement is made of limestone and when this is heated, it produces a clinker, which binds the elements of concrete together.”

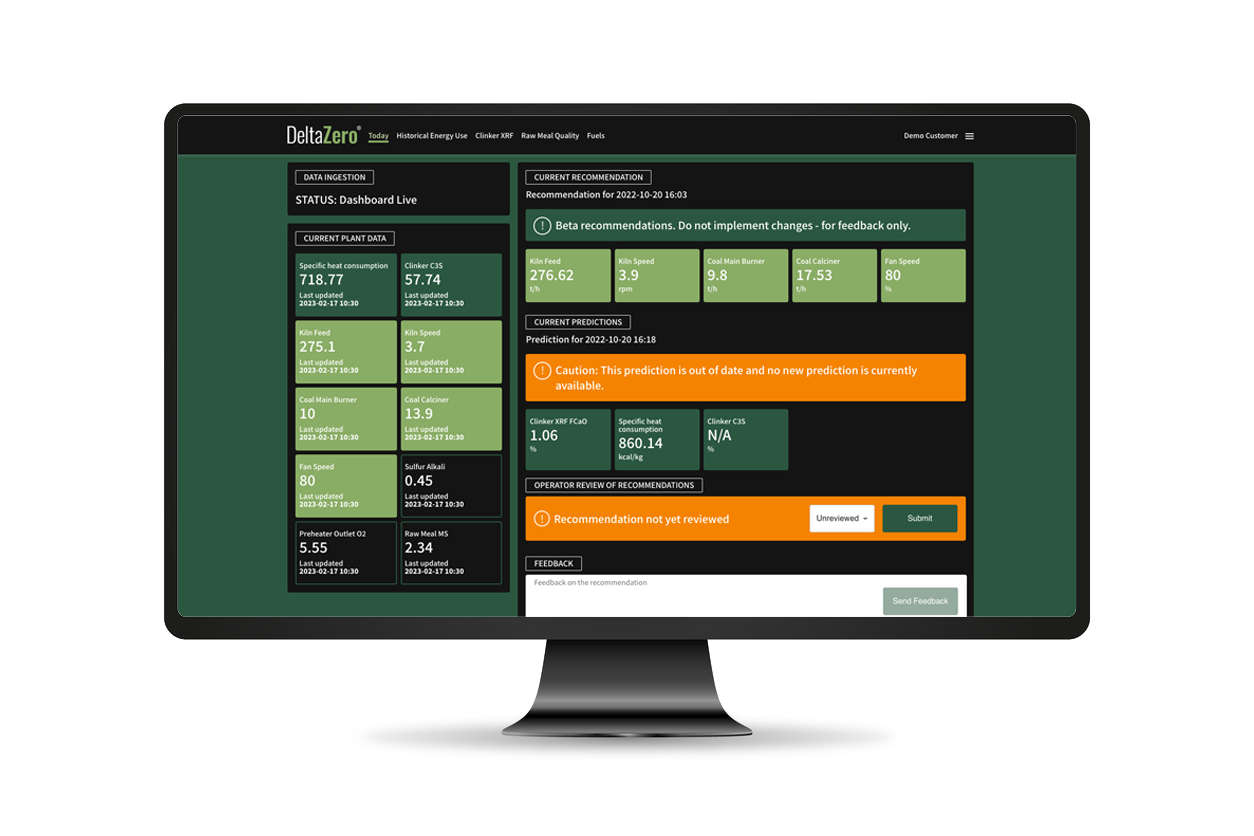

Delta Zero Cement, the spinout’s current focus, targets the critical pre-heater and kiln processes stages that account for thermal fuel use and emissions to optimise fuel use and reduce carbon emissions.

“But heating up this limestone produces CO2 which is responsible for half of the emissions in cement. This heating process is what we are targeting, as we take the telemetry from sensors, IT and the cement plant which gives us hundreds of data points that we use to build a digital twin of the process, then run live optimisations on that using machine learning,” elaborates Elsayed-Ali.

“This machine learning enables the plant operator to understand what is occurring in the cement making process at any given moment. This process is complex, and impossible to understand without the help of machine learning. We then recommend to the operator specific settings to optimise the performance of the plant on an ongoing basis, leading potentially to an 8% to 10% fuel usage drop which translates to a reduction in costs and emissions.”

Their other products, Delta Zero Glass and Delta Zero Steel are still undergoing research with the team working with non-profit organisations such as ResponsibleSteel to find an effective solution to decarbonise the production of these materials.

Sprouting climate-focused startups

Climate tech spinouts are becoming an increased focus for investors, according to a recent GUV analysis, and Elsayed-Ali isn’t surprised by this reality.

“I believe carbon-focused startups are becoming so prevalent because of the threat of the climate emergency on the economies in society,” he says. “The climate crisis will also lead to the biggest transformation in the way humanity operates, from how we produce and consume everything from food to textiles, so everything will have to change to adapt to our emissions reality.”

He adds: “This drastic change means there will be a massive economic opportunity as well. It is not a stretch of the imagination to say that over the next 30 to 50 years, every aspect of our economy is going to be much bigger than what we saw during the industrial revolution.”

Demand for green hydrogen and alternative fuels is only expected to take off by the mid-2030s, according to the International Renewable Energy Agency, but adapting our current methods is imperative as the planet cannot wait.

“We have to get to a point where we are producing no emissions, which will undoubtedly shake up our economy which is largely comprised of this,” says Elsayed-Ali. “So, I believe investors are becoming attracted to these startups because climate technologies are part of the future and will drive economic revenue.”

He continues: “At the same time, climate technologies are not fad-products. You see a lot of investment going into things such as cryptocurrency, which may garner initial success but are not necessarily essential. Whereas the transformation to a more climate-friendly economy is essential and will be a guarantee of the future.”

Investor relations and university guidance

Carbon Re was co-founded in 2020 by chief operating officer Buffy Price, chief scientific officer Daniel Summerbell, chief technology officer Aidan O’Sullivan and Elsayed-Ali himself.

“Like most startups,” says Elsayed-Ali, “we’ve had a few angel investors who helped us initially and without them we would not have prevailed as we have done.”

He adds: “In 2021, we began to receive investments from institutions such as the Clean Growth Tech Fund, the UK’s primary climate tech funder, as well as funding from our universities. They have been vital in not only our financing, but generating various connections and talking to people in the industry.”

In November 2022, Carbon Re raised $5m in a seed round led by a German-based impact investment fund, Planet A Ventures, with participation from UCL Technology Fund, Cambridge Enterprise and Clean Growth Fund.

“Part of our co-founders research at both universities informed a lot of our early ideas about where the company was going and the types of early products we wished to develop,” says Elsayed-Ali. “So, because of this, Carbon Re has received a lot of support from the university.”

He concludes: “We have also been supported by UCL Business, a subsidiary of UCL which has also provided strategic support as well as the university as a whole funding both of our rounds. Our team is greatly compromised of individuals who work for UCL and University of Cambridge such as Steve Evans at the Institute of Manufacturing in Cambridge. So, we have a strong relationship with both universities that we deeply rely on.”