A startup in China has developed a non-toxic alternative for transparent touchscreens. The nanofilm can also improve solar panel performance.

If you’re on the move and reading this, chances are your fingers are in contact with a conductive glass screen coated with ITO (indium tin oxide), a chemical that allows your mobile phone screen to react to your touch.

Glass itself isn’t conductive. When your finger touches the ITO-treated screen, the electrical field changes, telling the phone’s chip where your finger is. The conductive layer senses your touch, allowing the smartphone to identify which app or function you’re activating.

Electrical conductivity is what makes all of our technology work—it’s straightforward with metal-based materials. However, making transparent materials like glass or plastic conduct electricity is remarkably challenging

Currently, market options for touchscreen tech include ITO, nano-silver, and metal mesh. These manufacturing techniques are either complex (multiple layers), have visible nano-wires, are toxic, or are very expensive to produce. The transparency index ranges from 88% to 91%, with ITO at the lowest of the range. Your iPhone’s glass transparency index is 88%.

For starters, ITO is a toxic chemical. Studies with animals indicate that indium tin oxide is toxic when ingested, with negative effects on the kidney, lungs, and heart. A new occupational hazard called ‘indium lung disease’ has been identified. The first patient, a worker involved in the wet surface grinding of ITO, suffered from interstitial pneumonia with lungs filled with ITO particles.

A startup in China has developed a non-toxic alternative for transparent touchscreens: a nano-thin layer of silver between two nano-thin layers of substrates (such as plastic). It’s non-toxic, features low surface resistance that is more than ten times lower than ITO, ultra-high light transmittance, low haze, high flexibility, and a wide range of application possibilities. The transparency index is an impressive 91% because the silver is only a few nanometers thick. In fact, it’s so transparent it’s very hard to see the material.

Beyond touchscreens, different formulations of the highly transparent nanofilm made via physical vapour deposition (PVD) of metal can increase solar panel efficiency, enhance display performance, and improve energy efficiency of buildings and cars by blocking infrared light.

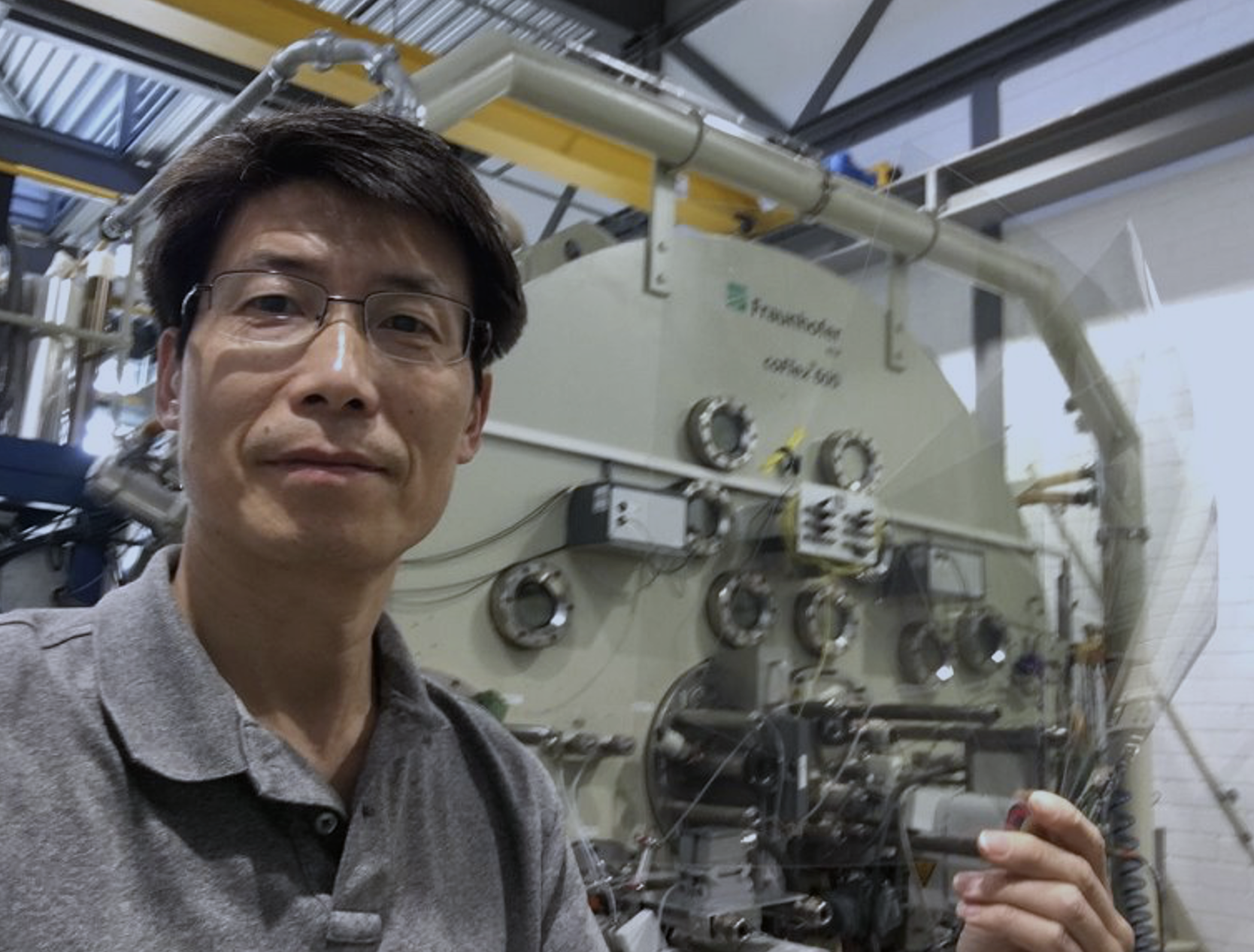

Incubated at University of Michigan and Beijing Institute of Collaborative Innovation (BICI), this material breakthrough was further developed by a renowned nanotechnologist, Professor Lingjie Guo at University of Michigan, with a research grant from BICI. Prof Guo developed a multi-element alloy formula for co-sputtering targets and a sputtering process — a method for depositing thin films on substrates — that avoids island structures common in the PVD silver deposition process. The result is a film that is clear, consistent, and smooth. Prof Guo has published this research in top international journals, such as Science Advance, Nature Communications, Adv Mater and more.

Zenithnano, the Beijing-based nano-conductive materials company, licensed the technology from University of Michigan. When CM Venture Capital’s founders Dr Patrick Berbon and Dr Min Zhou saw a sample from a mid-scale trial in 2019 they were impressed. CM Venture placed a Rmb30m (~ $5m) seed investment in the startup as a sole investor to further the tech. They had seen dozens of startups in the ITO-replacement field before and recognised immediately how unique and elegant Zenithnano’s material solution was. That sole seed investment from CM Venture kicked off a commercialisation journey.

Professor Guo holding an A4-size sample sheet cut from a 100m-long roll produced at Fraunhofer (it’s highly transparent; you have to look really hard to see).

Today, the material is produced at Zenithnano’s 19,700 m2 plant in Guangzhou, China. Made on the world’s most advanced roll-to-roll magnetron sputtering production line, the transparent, flexible, conductive nanomaterial has a wide range of uses. The roll-to-roll production process for Zenithnano’s conductive films is simpler than nano-silver and metal mesh formats, keeping costs low and affordability high.

What these breakthrough nanofilms can do for technology and the environment

1) Provide flexible and transparent electrodes for touchscreens and colour-changing windows

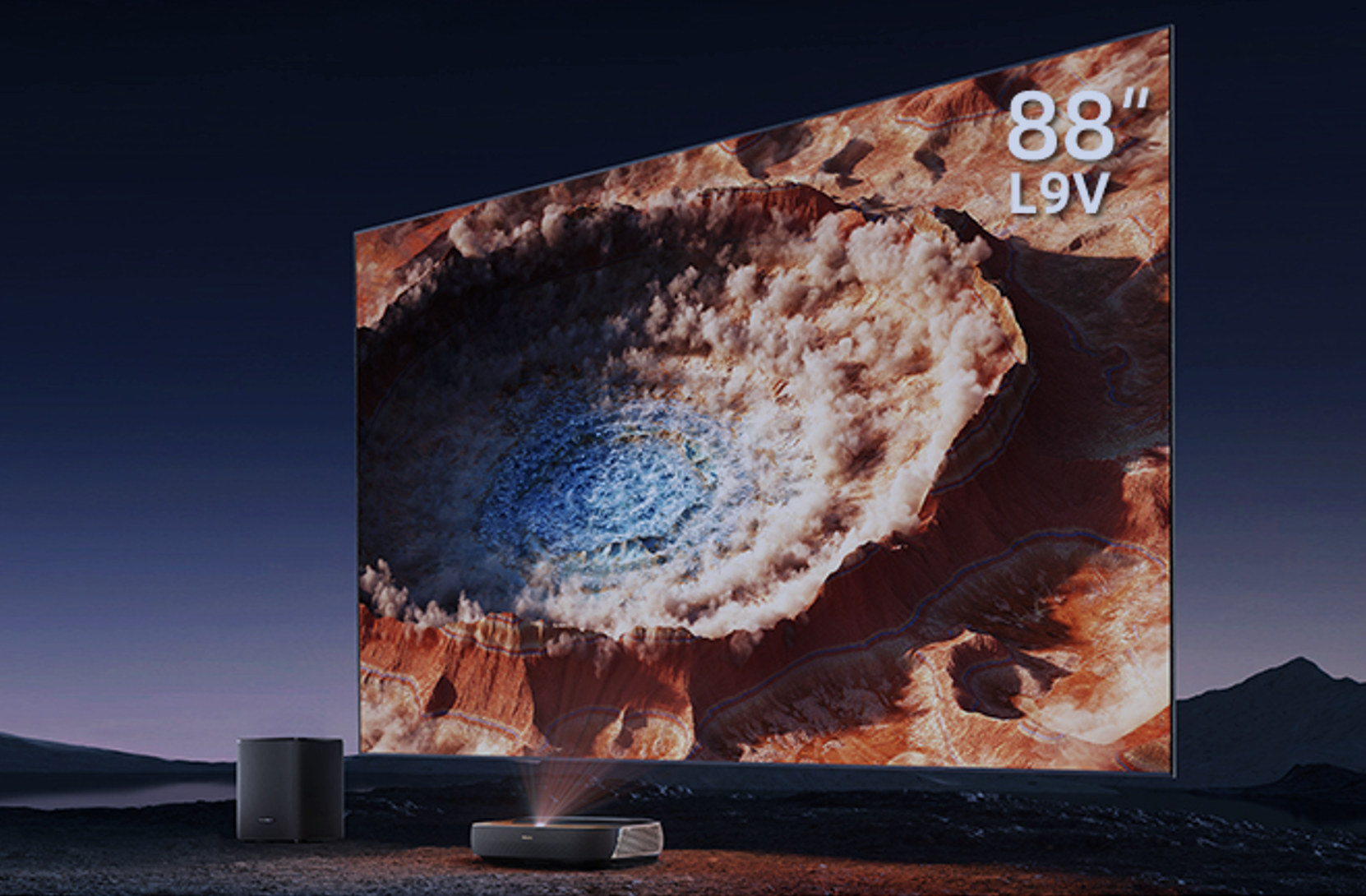

As a transparent conductive electrode, Zenithnano’s clear nanofilms have a thickness of 7 nanometers – compare that to a typical iPhone’s ITO-treated glass screen, where the ITO thickness is over 100nm. The material is flexible, bendable, not fragile like ITO, and perfect for a new generation of folding screens or large touchscreen TVs. It can be used in touch displays, electrochromic (tint/color-changing) windows, perovskite solar panels and more. Zenithnano’s electrode film can replace ITO-touchscreens for a thinner and more flexible product form, with better product performance from electrical conductivity that’s 10X better. The transparent electrodes can be used for colour-changing electrochromic windows on buildings and vehicles, helping to reduce our reliance on air conditioning and carbon footprint on a large scale.

2) Eliminate solar panel failure by keeping oxygen and moisture out

Since Zenithnano’s ‘nanofilm sandwich’ usually features unique metal alloys in between other thin films (such as dielectric material), adjusting the layers makes the perfect oxygen/water vapour barrier for quantum dots (QD), N-type and perovskite solar panels, which are constantly exposed to sun and rain. This is crucial, as perovskite, a key material that converts light to energy, becomes unstable in the presence of moisture, potentially leading to solar panel failure. Because of its high transparency levels and ability to keep moisture out, the nano-material is extremely effective for QD films, keeping QLED TV screens clear, sharp and bright for years.

3) Improve solar panel performance by reflecting light and heat

Solar energy requires constant light input to be effective, and as the earth rotates, the direction of the sunlight changes. When Zenithnano’s nanofilms are modified and used on the front of solar panels, the films do two things: they can filter out UV light for improved solar cell lifetime, and when they are used on the back panel they can reflect light back to the panels. Mirrors or polished metal are not typically used in these areas as they’re either fragile, heavy or too expensive. As a light reflector, the specially-tuned nanofilms can also be used as a reflective surface for laser projection TVs – essentially short-throw projectors – to reject ambient light, while keeping visuals crisp and clear. Not only can it be designed to block out UV but also IR, so the nanofilms make excellent window films for buildings and vehicles: the material can reflect 90% of infrared heat, without blocking visible light, reducing the reliance on energy-consuming HVAC systems.

With several product lines introduced in the market, Zenithnano is approaching close to $20m in revenue this year and growing fast. Next time you tap your mobile phone screen or think about the efficiency of your solar-energy system, consider the green innovation coming out of China.

This is a quarterly update on Chinese startups developing technology for sustainability and carbon reduction. In the next quarter, we’ll share another revolutionary technology we have discovered in the region.

CM Venture Capital is a venture capital firm that invests in renewable carbon, advanced materials science and hard technologies. Backed by Fortune 500 companies including BASF, BAT, GE, Henkel, Heraeus, Petronas, Samsung, SABIC, CM Venture Capital has a global reach, with a strong network in China